-

2018.07.11

The new management approach based on Kaizen by all 1 New chapter starts this time. I try to write a concrete approach.

*************************************

Last time, I mentioned that the means of management reform starting is Kaizen which is very familiar to manufacturers in Japan. It is not the imported means from America or Europe, the names of which are English language but the Kaizen that Japanese manufacturing industry used to for a long time. I have seen plants in many countries around the world including U.S.A., Europe, Asia, Australia, Africa, etc. From the experience, the greatest strength of Japanese manufacturing industry is Kaizen. Even now, the Kaizen power is very strong. So we should make use of this Kaizen power, and you can make drastic management changes if you use the familiar Kaizen power.

*******.*****************************

Question: Could you imagine the approach of changing management through Kaizen?

-

2018.07.04

The strong intrinsic which Japanese manufacturing industry has 14 I have written ” The strong intrinsic which Japanese manufacturing industry has “, this is the last session.

*************************************

Based on my 27-year career as a consultant, I am sure that the small and medium-sized manufacturing industry in Japan is the closest to overcome the big changes in the future. That’s because they can easily implement total optimal Kaizen.I am going to propose big management reform through this essay from next time, but the means to do it is “Kaizen” that everyone has been running all the time in Japan. All the members including president get together in the site of manufacturing and start total optimal Kaizen and raise a revolution.

*************************************

From the next essay I will start the series titled “New Management Approach Based on Kaizen by Everyone “. Thank you very much.

-

2018.07.02

The strong intrinsic which Japanese manufacturing industry has 13 Half of the year has passed. It will be the second half from July. Time flies!

*************************************

In the mass production era, production was done in large quantities in countries with low labor costs. but in the mass customization era, it is necessary to be close to consumers both in distance and in time. This is “to produce close to customers”. In addition to distance and time, it is that operators produce goods imagining the customers to be close to each other. Through consciousness and mind trying to find the real demand of the customers and make the original products which makes the customers happy. In other words, it can be said that this is a tremendous opportunity for Japan’s manufacturing industry that has worked hard on customer first principles.Question: Changes from mass production to mass customization, can you imagine?

-

2018.05.30

The strong intrinsic which Japanese manufacturing industry has 8 Producing and selling go together. We have to think both together.

*************************************

The first surprise was that they recognize that the speed of the market change was extremely fast and that they were working accordingly. This was a surprise for me, but it was also what I could imagine.

The second surprise was that the people whose responsibility were “Create”⇒ ‟Produce”⇒‟Sell” got together in one place and made immediate decision. The gathering member was not the people in one department or not a big conference which one person spoke, and the rest people just listened. all the related people stood up and each of them had a white board marker in front of the whiteboard and created the active solution.

Question: Have you ever held a meeting that in front of the whiteboard everyone has a marker and discuss writing on the board?

-

2018.05.30

The strong intrinsic which Japanese manufacturing industry has 9 The sun light is getting stronger. It is time to start taking care against heat stroke.

*************************************

Three people kept discussing although I an outside Japanese visitor was there. The person who guided me there told me that a big decision was made then there. If so, it is very prompt decision.

The walls in the corridor were all whiteboards and I saw plenty of people discussing in front of the boards. I was overwhelmed to see big decision done quickly in front of me. But taking time calmly afterwards, I thought that their way of making quick decision with the related people together is also the way which Japanese manufacturing industry was good at.

Question: I wrote that the great meeting which I saw there is what Japanese manufacture industry was good at. Do you agree with me?

-

2018.05.28

The strong intrinsic which Japanese manufacturing industry has 7 “The reason why we can produce them is because there are the customers who buy them.” We sometimes forget this fact. The essay this time covers my experience about this fact.

*************************************

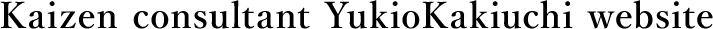

I said “All of you have doctorate degrees and I imagined that you are doing research in your own laboratory by yourself but you are not.”

Then their answer back was “We are not responsible only for developing products, but also for selling them. So we need to work together. It is absolutely impossible for one person to do all.”

In other words, they were responsible for doing their own tasks by exploring market needs, developing products, producing products and selling them.

There were two things that surprised me when I saw the work of the American top companies.

Question: What do you think is the two things that surprised me? Please imagine.

-

2018.05.01

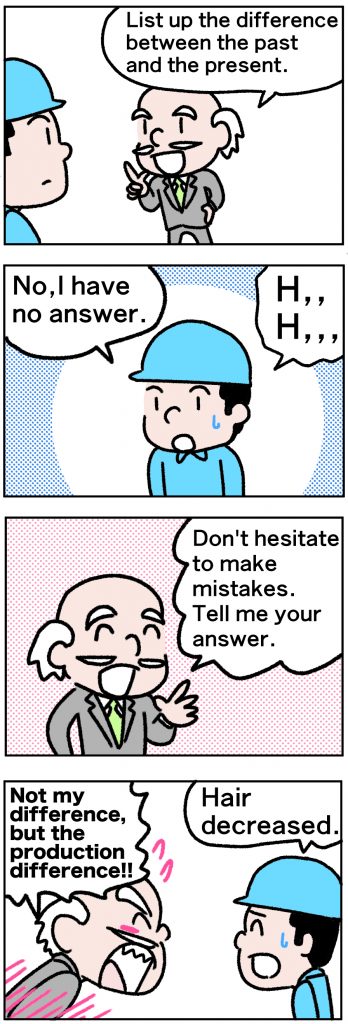

The strong intrinsic which Japanese manufacturing industry has 5 How previous Japanese manufacturing was done and what is the difference from present way?

———————————————————————————————

Unfortunately, however, many Japanese manufacturers currently do not recognize the true strengths that they themselves have inherently and have not made improvements and changes that make use of their strength.

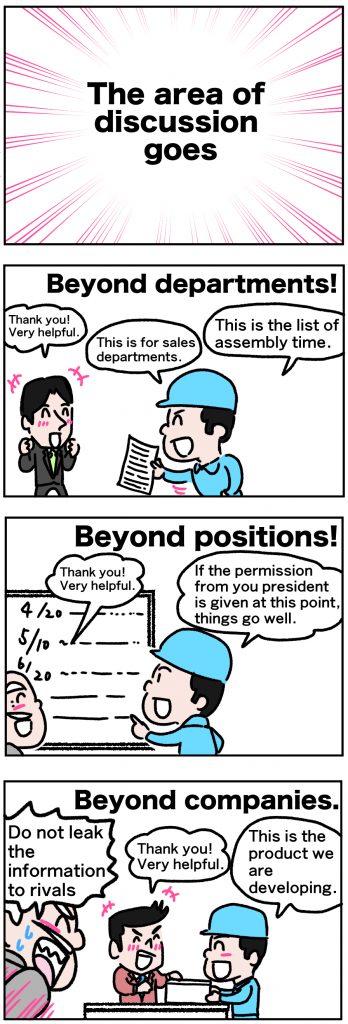

Japanese people have a strong sense of responsibility for their work. And often they do Kaizen of their work without being ordered. If there are occasions that related people regardless of department and position get together, they start discussing problems or targets and often get excellent solutions. Discussion beyond department and position was a good practice of Japan.

Question: In fact, what do you think Japanese people have a tremendous strength but they are not recognized?

-

2018.04.27

The strong intrinsic which Japanese manufacturing industry has 4 I believe the traditional Japanese manufacturing way is still strong. I will write about this matter.

*************************************

When Japanese manufacturing industry suddenly made a world debut and surprised the world with its high quality products, in Japan both the president and employees are working together on shop-floors to make products which make the customers happy. I found that kind of atmosphere when I read the biographies of Kohnosuke Matsushita the founder of Panasonic, Soichiro Honda the founder of Honda Motors, and Masaru Ibuka the founder of Sony. They work together with employees and got the best total solution.

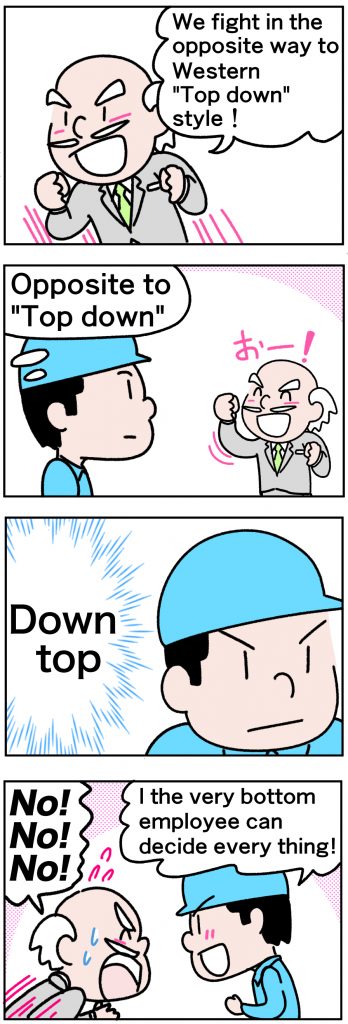

I am sure that this type approach is still important and useful management skill now. It is different from the Western top-down approach. It is done by all the people through Kaizen and these continuous small Kaizen makes big change in management.

Question: Do you see any difference between the manufacturing long time ago and now in your company?

-

2018.04.10

The strong intrinsic which Japanese manufacturing industry has 3 Last time, I wrote that the manufacturing in Japan is different from that of Europe and the United States, but what is the strength of Japan? I will talk about that this time.

*************************************

Japan is said that it lost the strength because of the digitization, which increased the modular type manufacturing and it does not require high skill to assemble which Japan was good at.

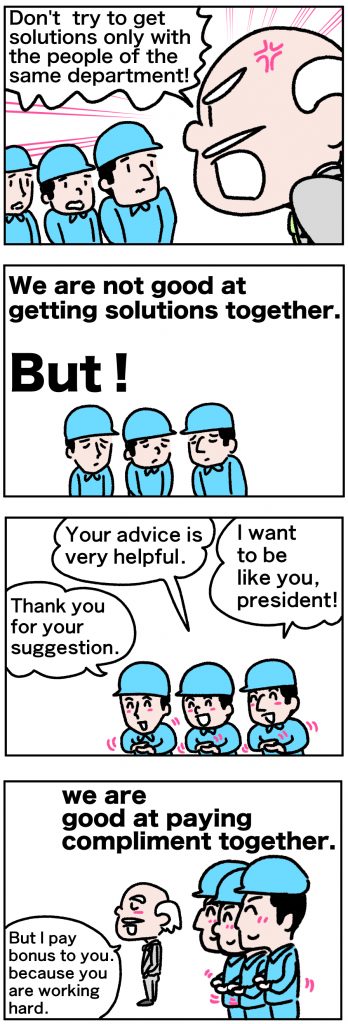

In the analogue era, Japan showed the strength in assembling the complicated products. But I think that the strongest skill of Japanese manufacturing is the power of getting ideas and motivation by getting together on shop-floor.

Question: Do you sometimes communicate freely with the people from all departments and positions in your company?

-

2018.04.05

The strong intrinsic which Japanese manufacturing industry has 2 I think that Japanese way of manufacturing is different from that of Western way. This time, I will write about it.

*************************************

Production of one product always involves all departments of the company. It is unlikely that you do everything from planning to sales, production, delivery, and payment collection by yourself.

If the people from all the departments relating a product get together on production shop floor and start talking about it, I am sure that you will get many excellent ideas. The people from marketing, design, sales, purchase, production, inspection and delivery department get together. The ideas will support the management of the company. This unique approach by Japanese companies is bottom up approach and very different from the Western top down approach.

Question: Does your company have opportunities for people in various departments to talk about products together?