This is the first report in 2018. I am going start a new topic which is more concrete.

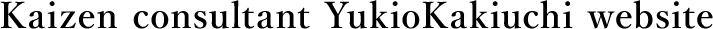

I am sorry to say but the manufacturing industry in Japan clearly has lost its competitiveness.

I will analyze the reasons in Chapter 1. And in Chapter 2, I will clarify the original strength of Japanese manufacturing industry. In Chapter 3, I would like to propose how to strengthen Japan’s manufacturing.

Chapter 1. Changes in the world and the problems with Japanese manufacturing industry

There was a time when Japan’s manufacturing industry was leading the world. At that time, Q, C, D (quality, cost, delivery time) was the basis of competitiveness, and outstanding Kaizen on the site played a big role.

And Japan had many hit products like Sony Walk-man or good quality compact cars which showed the Japanese technology.

However, nowadays, Japanese manufacturing industry has lost its momentum.

What happened?

Request. I will tell you my answer next time. Please think two or more answers to this question by that time.

I would also like to hear the opinions from you, and I hope discussion starts.

-

2020.02.28

[68] The new management approach based on Kaizen by all Let’s wash our hands much more frequently to prevent atypical pneumonia!

*** *** *** *** *** *** *** ***

Lead time reduction cannot be achieved by the president alone. Experts alone cannot do it either. This is a theme that really requires the participation of all the employers and all the employees. In a normal company organization, each person can only do his or her job. It is not easy to discuss improvement between different departments, even if they are related to each other. However, on the other hand, people from various departments gather on Genba and discuss their relations and problems about the products, synergistic and surprisingly large effect will be delivered, and in the process you can get high motivation.

The president gather the Kaizen that have been implemented separately by each department and determine themes of overall optimization. Then the small Kaizen by each people gets together and they become big and start supporting the company’s strategy.

*** *** *** *** *** *** ***

Question : Have you had an experience of this type Kaizen?

-

2019.10.28

The new management approach based on Kaizen by all 15 I would like to express my sincere condolences to those affected by heavy rain.

*** *** *** *** *** *** *** ***

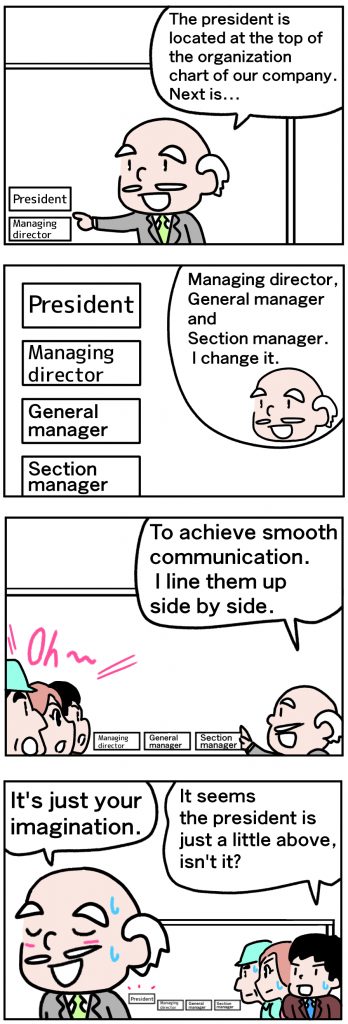

Top management must know the real site all ways. It is important not only to look around the site, but also to communicate with the people who work at the site. For example, Mr. Toshio Doko, the former president of Toshiba left the following words:

“The organization chart of the company is made the president at the top, followed by general managers, and section managers, but I don’t think that style good. On the job, both the president and employees are standing at the equal level. The main point of the meeting is to do it casually. You can hold a meeting while standing. Communicate with your subordinate when you see his ore her face. ”

*** *** *** *** *** *** *** ***

Question: Do you really communicate casually?

-

2019.08.30

The new management approach based on Kaizen by all 14 The terrible hot summer seems to be going away little by little. I am happy about it.

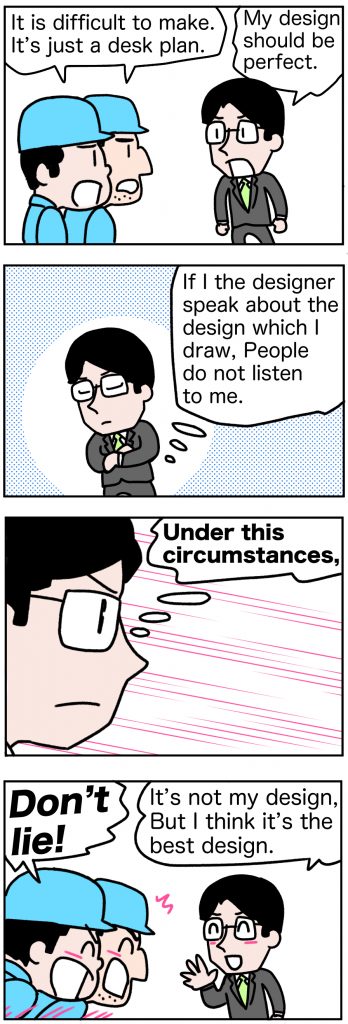

If designers talk about their job, you take it as a matter of design. But if operators talk about their job, it is not only their job but also about everything of the company. There are tremendous volume of information on shop floor. It is good to do free discussion with the people from many department with the operators and you can go beyond the walls that exist between the departments.

****************************************

Question: Are you talking with the operators in your company?

-

2019.08.05

The new management approach based on Kaizen by all 13 It’s hot these days and time of heatstroke has come. Water supply is important!

****************************************

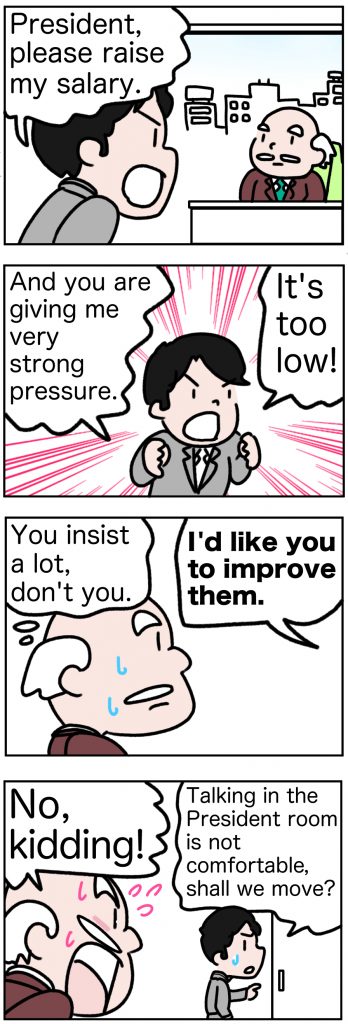

For example, all the workers know real things by experience. However, it is important whether those people can open their minds and talk about these experiences. Therefore, the various information that come out of KZ method or Choco-Ann are valuable. And It becomes possible for the president, the departments of design, purchase, sales, technology etc. to accept the experience of them on-site.

The part-time operators may be nervous and may not speak well if called in the president’s office. However, if the president goes to their job site and asks questions about his or her work and Kaizen improvements, the conversation boils. It may be possible only in such a way that the people of wide range roles such as the president, managers in other departments, leaders, full-time and part-time workers gather in one place and talk about one thing.

****************************************

Question: Are you talking with wide range of people in your company?

-

2019.07.09

The new management approach based on Kaizen by all 12 It’s hot these days and time of heatstroke has come. Water supply is important!

***********************************

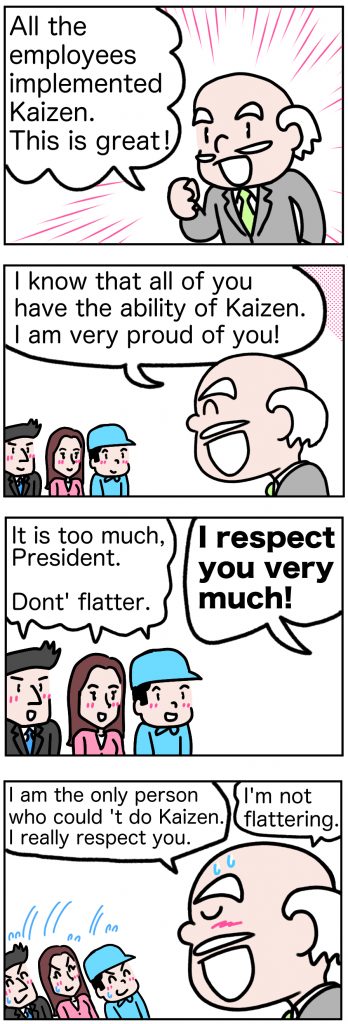

For that purpose, it is good for everyone to have a habit of implementing Kaizen continuously. Therefore all the employees are required to implement at least one Kaizen a month. The required level of Kaizen is very low. You can copy the Kaizen of your coworkers or just repairing your tool is also Kaizen. Choko-Ann’s rule is very loose and no need to have financial result and you are always praised.

All the people join the Choko-Ann activity and the president find the fact that all the people of the company have the ability to do Kaizen and start improving the management together.****************************************

Question: Can you imagine the Kaizen that copying and repairing is OK?

-

2019.05.28

The new management approach based on Kaizen by all 11 The long holidays are over and Let’s work hard again!

***********************************

The Choco-Ann method is a way to bring out the improvement ability of the employees and execute the improvement idea in the company. There are many ideas in the company, but they are worthless unless they are implemented. It is required to improve the various problems found through the implementation of the KZ method. And it is necessary for everyone in the company to realize as many ideas as possible in a short time. When it comes to how to achieve that, most things come true if you can think of a way to do it rather than looking for reasons you can not do it.

****************************************

Question: How is the improvement implemented in your company?