-

2018.03.30

The strong intrinsic which Japanese manufacturing industry has 1 I have written about “Change in the world and the problems with Japanese manufacturing industry”. From this issue, I start writing about “The strong intrinsic which Japanese production industry has”.

**************************************************************************

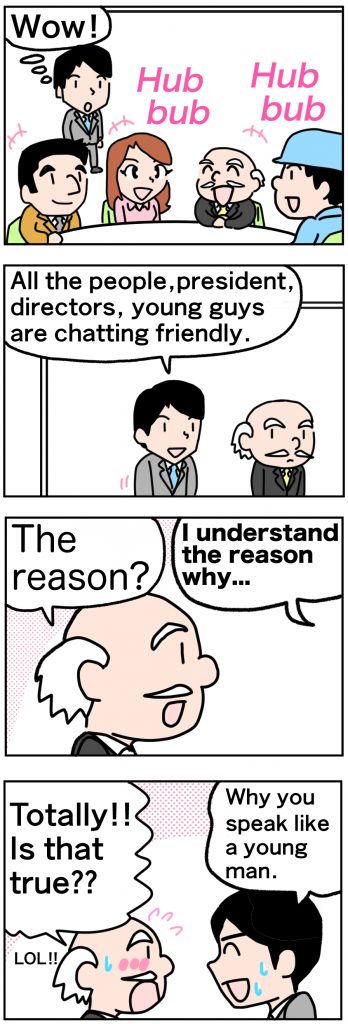

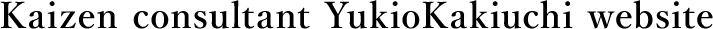

I have worked as Kaizen consultant so far and I would like to introduce what happens on shop floor. As my title is Kaizen consultant, the presidents who use me expect to improve the work efficiency and product quality by applying Kaizen technic on shop-floor.

However, in addition to the improvement of work efficiency and product quality, development of new products or new markets often occurs. But as I have no experience or knowledge in developing new products or marketing, it is certain that the result is not brought by my guidance.

I do Kaizen on shop-floor wearing the work uniform of the plant. The important point is that there are always the president and other top people from design, sales, marketing, engineering and so on. All of us do Kaizen on shop-floor together and in the process of this activity, there may be the clue to the development of new products and new market.

Question: Have you ever experienced that super ideas came out while all the people are doing kaizen and chatting on site?

P.S. I received the title “Advanced Technology Meister FY2017” from the Ministry of Economy, Trade and Industry. I am happy.

-

2018.03.19

Change in the world and the problems with Japanese manufacturing industry. 8 What should we do against various changes?

*** *** *** *** *** *** ***

By my observation, these changes are not temporary, and it is the result of changes in the business environment. Management must start fighting against these changes. Managers need to abandon their successful experiences so far and start their management reform with the intention of reviewing everything from scratch. Their future is not on the extension of the past experiences.

Then, how can we improve our production management? Is there a way of improving our production way without staying in the conventional way of our Kaizen or improvement?

Looking at the media reports, there are plenty of pessimistic information about Japanese production industry.

Question What kind of Kaizen do we need?

-

2018.03.09

Change in the world and the problems with Japanese manufacturing industry. 7 Last time, I wrote about what is coming in America. What is happening in Japan?

*** *** *** *** *** *** ***

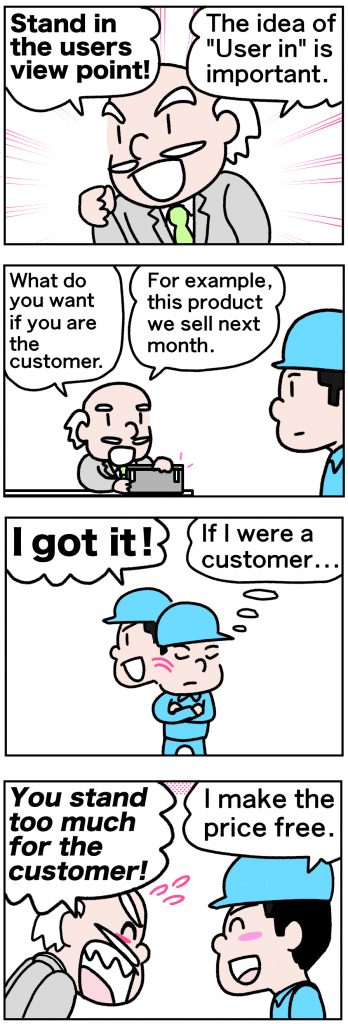

Mr. Kentaro Ohyama, the president of Iris Ohyama Inc. named the coming era as “User in”. The era of “Market in” is going away and we have to face the customer more directly. To have the ability to respond the customers’ requests which are very different each other is becoming more important.

And recently, information technology such as AI(Artificial Intelligence) has advanced very rapidly. In addition to AI a variety of new information technologies such as IoT and Big Data processing, or new manufacturing technologies like 3D printers are born, it is also important to have the technical ability to respond them immediately if necessary.

In the era of mass customization and user in, we must have the wisdom and technology to use and develop the essence of these innovative information and manufacturing technology.

But it is said that Japan has been very behind America and Europe in the field of the total information technology like Industry 4,0.

Question Do you also think that Japan is behind?

-

2018.03.05

Change in the world and the problems with Japanese manufacturing industry. 6 There are various names for the coming era. What kind of names are there in America?

*** *** *** *** *** ***

In English “mass customization” may be the word which shows the coming trend of manufacturing. In the coming era, as the consumers already have most of the things they want, you do not buy it unless you really like it and the price is as reasonable as the mass produced products.

From the view point of production, even if the consumer demands become very individual, the production cost should be as low as the mass production. This is the mass customization. Then it is required to develop products which take customers’ request one after another, take orders, produce them and collect payment in a short time.

It can be said that the market and the manufacturing are changing from the era of mass production to mass customization.

Question : The time may come when the price is low even for individual custom production. The 3D printer shows the new way of custom production. Have you already seen this trend?

-

2018.02.23

Change in the world and the problems with Japanese manufacturing industry. 5 But from now on, competition starts from finding real customer needs because the competition will be done based on attraction quality assuming that functional quality is good.

The important lead-time is not only the production lead-time so far but also the total lead-time starting from finding out the customer needs, design it, produce it and sell it with reasonable price in a very short time from now on.

I name this lead-time “customer satisfaction lead-time” and Japanese production companies should shorten the customer satisfaction lead-time rather than the production lead-time.

In order to cope with it, all the company skills not only production engineering and Genba Kaizen but also marketing, designing, and sales should get together.

Question : Previously quality was evaluated mostly by function but these days by attraction. What do you think of it?

-

2018.02.09

Change in the world and the problems with Japanese manufacturing industry. 4 This time, I will start talking about changes in the market and manufacturing.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

This means that Japan’s manufacturing industry can not survive just by doing 5S, removing wastes, or shortening production lead time, which have shown a lot of good effect so far. In order to acquire the strength again, we have to understand that we are entering new era in which new improvement and further change are required while keeping the on-site improvement ability which we have made so far.

Then, what kind of change is coming in the future? Consumers already have most of the things and they do not show interests except what they really want, and even if they are interested they will not buy it if the price is high.

It has been said that if you make a good product you can sell it, but the good product then was the product with high functional quality. So Japanese manufacturing companies have been improving quality and cost competitiveness. In other words, competition has been in the field of production engineering and Genba Kaizen ability for high quality and low cost.

Question : I wrote that consumers have been changed. What do you think?

-

2018.02.06

Change in the world and the problems with Japanese manufacturing industry. 3 Last time I wrote a visible part of the changes in the world. And this time I will write about invisible part of changes in markets and in manufacturing.

Markets themselves are also changing drastically, and as a result manufacturing has been forced to change too.

In the era when all the products were sold out, it was called as the product out era and the production process was simple, mass production with small variety. At the time, on-site improvement activities that realized quality improvement and efficiency improvement like the QC circle expanded production capacity and produced great results in improving profitability.

After that, when the variation increased gradually, it shifted to the production of small-lot size with a lot of variation, which was called as the market-in era. At that time, to respond to the customer orders without making the customers waiting although with very small amount of inventory, many Japanese manufacturing industry studied Toyota production system. That helped the Japanese manufacturing industry to get shorter production lead-time and to be profitable and they got high reputation.

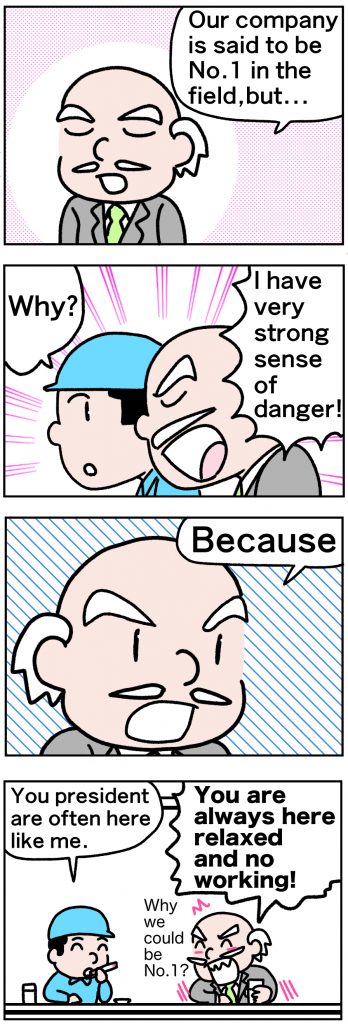

Nonetheless, in Japan many small and medium-sized companies have already disappeared due to bankruptcy or lack of successors. And many companies which show good level of 5S and have done high level Kaizen like removing Muda or wastes are facing difficulties that their products are not selling as before or their profits are not as big as before.

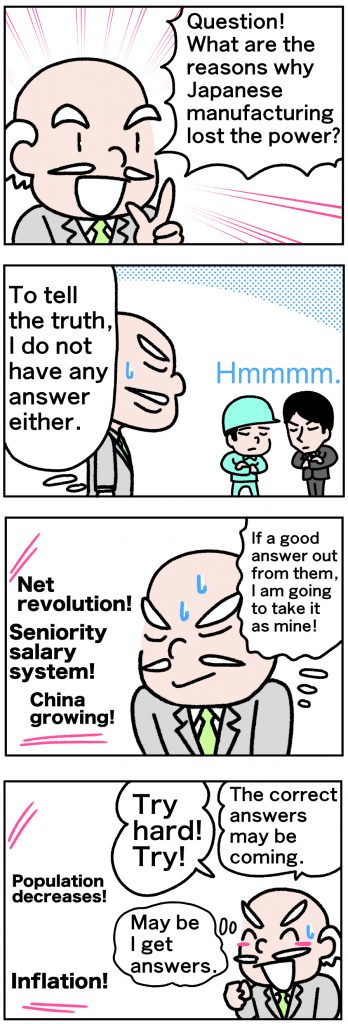

Question: The level of Japanese manufacturing industry is high represented by Toyota production system. Nevertheless, many of them are facing a lot of difficulties and struggling . What are the problems?

-

2018.01.29

Change in the world and the problems with Japanese manufacturing industry. 2 What are the reasons for it?

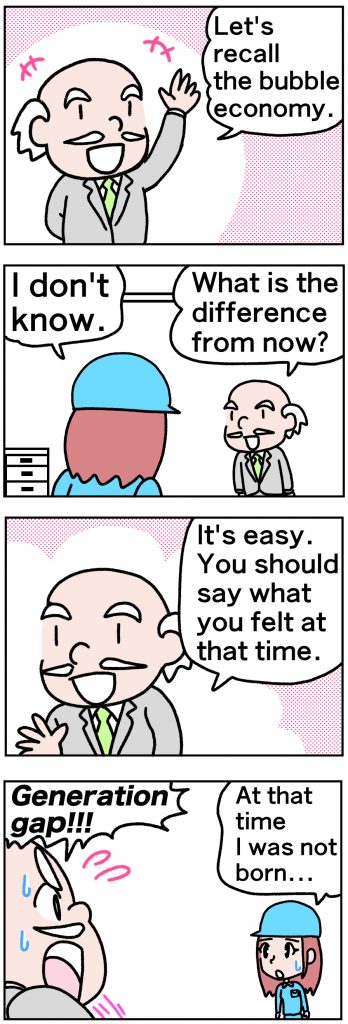

In Japan, wages have started to rise with the improvement of national strength and it has used foreign low wage workers and has produced some parts abroad. However, sales declined extremely due to the collapse of the bubble economy, and significant cost reductions were required to maintain profit. Then many home electric product industries relocated their production bases abroad.

As a result, domestic work decreased, and technological outflows occurred.

In home electronic products, sales declined due to lack of adaptability to local needs. In addition, in digital home appliances such as flat-screen televisions, cost competitiveness declined due to delays to global procurement of parts in modular production.

In the automobile industry as well, in the results of the JD Power US car quality survey in recent years, evaluation of quality has been changing from function quality to design quality, and Japanese cars are not evaluated so high as before.

Furthermore, a sharp decrease in the labor force has occurred due to aging of the population and decreasing birthrate, the quality and quantity of workforce has been short, and the problem of job skill handover also becomes serious.

For example, there are many foreign workers who do not understand Japanese at the site of production and temporary employees who have little experience even if they are Japanese. There are also generation alternation due to mandatory retirement by age.

Among them, there are many companies that have stopped Kaizen or continuous improvement.

Question I wrote what are happening on the production sites. But I am sure there are a lot more happening. Please tell me your experiences.

-

2018.01.22

Change in the world and the problems with Japanese manufacturing industry 1 This is the first report in 2018. I am going start a new topic which is more concrete.

I am sorry to say but the manufacturing industry in Japan clearly has lost its competitiveness.

I will analyze the reasons in Chapter 1. And in Chapter 2, I will clarify the original strength of Japanese manufacturing industry. In Chapter 3, I would like to propose how to strengthen Japan’s manufacturing.

Chapter 1. Changes in the world and the problems with Japanese manufacturing industry

There was a time when Japan’s manufacturing industry was leading the world. At that time, Q, C, D (quality, cost, delivery time) was the basis of competitiveness, and outstanding Kaizen on the site played a big role.

And Japan had many hit products like Sony Walk-man or good quality compact cars which showed the Japanese technology.

However, nowadays, Japanese manufacturing industry has lost its momentum.

What happened?

Request. I will tell you my answer next time. Please think two or more answers to this question by that time.

I would also like to hear the opinions from you, and I hope discussion starts.

-

2017.12.28

Chatting at work is important 5 I have written that chatting with common theme on shop-floor is important.

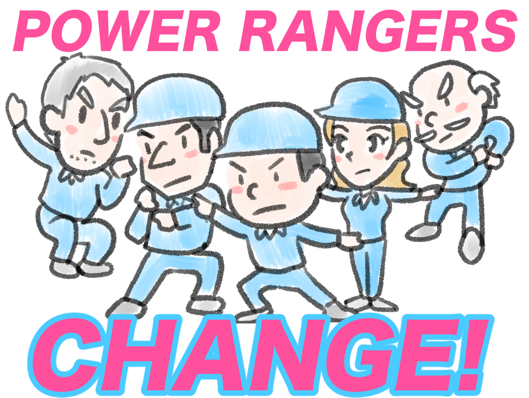

This time I want to tell you the image of this activity.

This is the logo picture of my company and it tells the feeling.

A young leader Kaizen-kun is standing in front of the group and the other people of the company are supporting him. The person on the right is the president, on the left is me.

Please do Kaizen like this. It must be enjoyable, and you will get a super result.

I wish you a happy new year!