I finally put all the data in my lap-top computer to cloud. I once spilt coffee over it and had a very big trouble but I am OK now. I am very happy.

*************************************

Furthermore, there is some information that Japan is largely behind in the information technology field like Germany’s Industry 4,0 or the American Industrial Internet, but is it true? Japan has been doing Kaizen activities such as QC circle for a long time, and there are already many experiences and data accumulation on the field. This was rarely found in Europe and the United States, and it can be said that the Western countries finally became ready to take the data of the site like Japan with the help of IT.

Question: I think the data on the plant site in Japan is really amazing. How about your company’s data?

-

2019.02.14

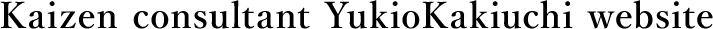

The new management approach based on Kaizen by all 9 It is the season of flu. Let’s wash hands as often as possible not to catch cold.

**********************************

Before starting the new Kaizen approach, let me tell you my Kaizen methods.

I do Kaizen with the president and other managers on shop-floors wearing work uniform. If you do Kaizen, the shop sites always become better than before. But we are not satisfied by the result, but we start discussion why we needed to do Kaizen to know the root cause.

Through the discussion we often get the conclusion to change the product-design, machine lay-out, information exchange between sales department and manufacturing department etc. Those conclusions are big and impossible to get by the single department activity. Through these discussions, I have a lot of experience to create new products or new markets.

For example, I often use the KZ method to do this type discussion. We do 5S with the president, managers of the company, normal employees. They are from manufacturing, engineering, designing, sales, control etc. And in front of the big volume unnecessary things, they discuss “What is this?”, “Why they became unnecessary?”, “What can we do?”

Through this discussion, they get the company wide optimal improvement, they break the strong organizational barriers between divisions, and a comprehensive optimal system is created that everyone can cooperate and improve.

***********************************

-

2018.12.25

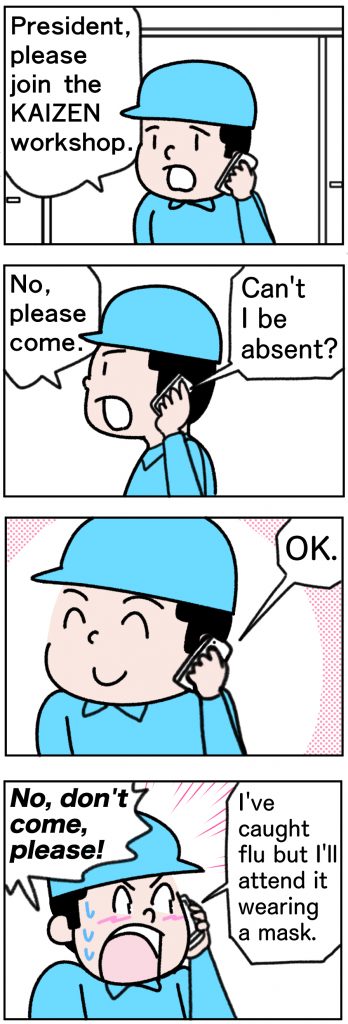

The new management approach based on Kaizen by all 8 Therefore, I would like to propose one way of management to the managers of small and medium size manufacturing companies in order to survive and prosper. Using the ability of Genba-Kaizen (on-site improvement) we give customers pleasure and surprises by showing the high performance of product development, design, production technology. Each method is never new or unusual, but it is possible only by the small and medium size manufacturing companies. It is rather difficult for large companies.

-

2018.10.12

The new management approach based on Kaizen by all 5 I have been waiting for the comfortable cool autumn. Now I am in autumn and happy! The summer this year was so long.

*************************************

From now on, it is necessary to do Kaizen with other departments to cover the whole. It is useful not only to divide tasks but also to work together at times. There are also ways that does not necessarily obey past processes such as emphasizing organization or hierarchy. In other words, it is necessary not only to adopt the logical management based on the past, but also to incorporate elements such as inspiration, motivation or empathy.

Also, in the past preparation was very important in order not make mistakes, but from now on you will quickly start Kaizen to find hidden problems by failing quickly. You need a sense of speed to complete the development quick. Up to now we were proceeded with the talk based on past data and hypotheses, but from now on there will be scenes where they are useless. It is necessary to obtain real information through real field observation.

*************************************

Question:What do you think about failing quickly is good?

-

2018.07.25

Yukio Kakiuchi’s Kaizen diary 1 I start writing Kaizen diary every other week.

**************************************

My consulting is done at your factory. You don’t come to my office, and I visit your factory. I move a lot and I use trains every day.

For example, last week, I worked for five companies. Monday: Maibara, Tuesday: Mikawa Anjo, Wednesday: Maibara, Thursday: Yamagata, Friday: Fukushima.

The trip was quite relaxing because I was in the reserved seat of Shinkansen all the way. I have kept this life for 27 years, so I have made a routine motion.

The belongings are an eki-ben (station bento food), bottled tea, confectionery, books. For one hour after getting on Shinkansen, I enjoy relaxed time eating, drinking, reading. Then I start writing and studying with my lap-top computer.

-

2018.07.11

The new management approach based on Kaizen by all 1 New chapter starts this time. I try to write a concrete approach.

*************************************

Last time, I mentioned that the means of management reform starting is Kaizen which is very familiar to manufacturers in Japan. It is not the imported means from America or Europe, the names of which are English language but the Kaizen that Japanese manufacturing industry used to for a long time. I have seen plants in many countries around the world including U.S.A., Europe, Asia, Australia, Africa, etc. From the experience, the greatest strength of Japanese manufacturing industry is Kaizen. Even now, the Kaizen power is very strong. So we should make use of this Kaizen power, and you can make drastic management changes if you use the familiar Kaizen power.

*******.*****************************

Question: Could you imagine the approach of changing management through Kaizen?

-

2018.07.04

The strong intrinsic which Japanese manufacturing industry has 14 I have written ” The strong intrinsic which Japanese manufacturing industry has “, this is the last session.

*************************************

Based on my 27-year career as a consultant, I am sure that the small and medium-sized manufacturing industry in Japan is the closest to overcome the big changes in the future. That’s because they can easily implement total optimal Kaizen.I am going to propose big management reform through this essay from next time, but the means to do it is “Kaizen” that everyone has been running all the time in Japan. All the members including president get together in the site of manufacturing and start total optimal Kaizen and raise a revolution.

*************************************

From the next essay I will start the series titled “New Management Approach Based on Kaizen by Everyone “. Thank you very much.