-

2017.10.03

Let’s hold Kaizen presentation meeting! This photograph shows Kaizen presentation meeting held at Company K which I visited the other day.

Once a month in Company K using 30 minutes after lunch several people present their recent Kaizen in front of all the members.

I propose a method of Kaizen called “Choko-An”. The content of topic No.7, ” The president does Kaizen, too “, is this Choko-An and Company K carries out this method.

I recommend to hold a presentation meeting of Kaizen because it is very good way to carry out Kaizen in order to obtain a big fruit continuously.

Speaking in front of many may make presenters a bit nervous, but memorizing speech is unnecessary because the Kaizen is done by oneself. I ask them some easy questions about the difficulty they had while doing Kaizen, concerning about what kind of result was produced and why you did it while showing photographs with a projector.

Everybody who hears such stories understands the whole company situation related to other fellow workers and other section matters through the information about the trouble that the people encountered and the result of the Kaizen. And finally, a small gifts are handed to all presenters after the plant manager evaluating those Kaizen, and praising their effort.

There might be so many people who are not good at talking in front of people, but they can surely talk by all means because those Kaizen are carried out by themselves. And proper preparation can be transferred to everybody well. Because the talking power proportionally increases the thinking power, so you will understand that Kaizen power improves along with this way. Then with the challenge of all the members, they can prepare for the severe change in the future.

-

2017.09.27

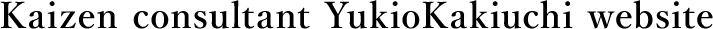

Kaizen before Tokyo Olympic It is less than three years till the Tokyo Olympic games. Various preparations will be carried out for it in Tokyo, Japan. In other words, the Japanese economy may be kept in good level because big money is spent for the preparation and money turns around in Japan.

However, the population of Japan keeps decreasing then and the shrink of the Japanese market and the decrease of the working population will suddenly come out after the Olympic and the Paralympic games are over.

Therefore, for these three years when economy is maintained, it is necessary to carry out Kaizen and to change all including producing processes, designing, controlling stock level, selling products and so on dramatically. We must prepare before that a big change will happen in four years same as preparing an umbrella if it will rain tomorrow.

However, there are many companies which are already busy and complain to have no time to do Kaizen. But there is no meaning to explain why you cannot implement Kaizen to me a consultant. Because four years will surely pass.

Let’s stop saying the reason why you cannot do, instead think how to do.

Actual examples will be shown in the next topic.

-

2017.09.19

Technical skill and technology in the future I have talked about a technical skill and technology that I found on the shop-floor twice. This time, I would like to write how we should proceed and improve the technical skill and technology in the future.

In bookstores I can find many books titled as “Work to disappear for another several years…”or “Menace of the robot…”.

Because of the progress of a computer technology, many incredible matters happened as the world champion of Go game was beaten by the computer. We tend to feel the pressure that people are robbed of their job by robots.

I have often been asked “what do you think will happen from now on?”, and now I got a clear answer recently. Like Mr. S the plant manager of the topic No.9, we are not used by computers but we use up them. We progress and improve more by utilizing computer and do not need to worry about.

Then what should we do in order to do so? But…recently we are used to the current situation, and do not feel the needs of Kaizen, don’t we? If so, it is a big problem. There are still so many insufficient things around us.

For example, the quality of our products are far from perfect and the yield ratio is still low. There are no computers and facilities which elderly persons can easily work with in spite of necessity while population is decreasing. There are surprisingly many things to be improved.

Do you try to change all of the things that you should change around you? Then the technology for that purpose become necessary, and at that time I think that the progressed computer supports us as a convenient tool.

-

2017.09.15

Wearable camera Recently for the motion Kaizen I use a wearable camera which is sold at the electric appliance stores. Many varieties of wearable cameras come out if you enter “wearable camera” in Amazon web page. The weight is only dozens of grams, a very light video camera.

For example, if you want to make an assembly operation video, you put the video camera on your head and video the hand movement. And if you explain the operation while doing the job, you can produce the video with the voice explanation.

In the past, video cameras were big, it was impossible to wear it. Then a camera person should take vide behind the operator. Then it was difficult to take a good picture, the hand motion not visible and the voice not clear. In addition, the operator became nervous when he or she felt being taken video.

In this sense, you can make a very good very easily when you use the wearable camera.

And splendid Kaizen plan comes out from the members if you watch the operation with a slightly big screen such as a tablet computer together on the spot.

The wearable camera is a product of recent technology. You can easily take the picture which is easy to watch clearly, but was not possible in the old days.

-

2017.09.05

Plant manager started computer Computers were called “electronic calculator” in the old days, but they are artificial intelligence (A.I.) these days and people talk that the computer may take over human work.

I have sometimes expected and sometimes worried what in the future would happen.

But I came across a splendid Kaizen related to this topic the other day in Company B.

Company B produces press dies. Recently the performance of the metal sheets are very high, much lighter and much stronger and it causes “spring-back” that is easy to be back again after the metal is bent. As the result, the dies became complicated, and the die design also became difficult.

Therefore, the company B purchased a computer software which could simulate the complicated spring-back phenomenon. Then, 60-year-old Mr. S the plant manager who he did not like computers and he did not touch them till then, but he decided to learn it from young engineers and became capable to use the simulation.

I asked Mr. S what happened to the engineering? Mr. S having high-level experience and technical skill becomes able to use the software of a recent technology.

Mr. S answered, “This software is so great. Before I repeated work in so many times till I get the final shape, but now I can get it by one trial!”. Thanks to the software, the productive capacity went up, and the communication with the young engineer was improved. And I am going to challenge ●●●● which is Don’t you think this is miracle?”.

Mr. S’s skill level became much higher by applying IT. It is not that his skill was taken over by IT. I saw a very good example how to use IT technology.

COMICS

1. Though I could not use the computer, I learned it and it was good!

Why?

2.Because the productive capacity went up, and the communication with the young people became much better.

3.Though secret, it is — now.

What is it?

4.I pretend to work and enjoy YouTube.

Don’t do that!

-

2017.08.25

KZ method I wrote that the president should also carry out Kaizen last time. There are several types of Kaizen which the president may participate in. And KZ method is the one of them.

K of the KZ method stands for Kaizen, and Z for Zentai which means “total” in Japanese. If the president join KZ method, not only the place is refreshed but also a big problem of the whole company will be found then and there. And total management kaizen will be started that was not possible until then.

To start KZ method, the president, the directors and the managers of sales, design and control section and production section may be gathered in the small area of the plant. And they are asked to stick cards on things which may not be used within a month or have problems.

Then, the card attached things are carried out of the place and divided into three categories, things not necessary, things not to be used within a month but may be used later and things necessary but with problems, then all the members start discussion.

・What is this?

・Why hs this become unnecessary?

・How should we do Kaizen together?

Through the discussion by the wide range of the company people in the plant, variety of the big companywide problems might come out, for example the problems of the design, the procurement, the sales and the control section will appear. And by observing such things and listening to the peoples opinion, the president understand the situation and start to suggest design change to all of the relating section people, as the design, the engineering and the production section or directs the procurement section to buy goods just needed or in smaller size, or orders the production control and the production section for changing the production lot size. These orders cannot be implemented by a single section.

Because the president watches the real things by himself, he can order them with confidence.

-

2017.08.18

President also does Kaizen I have written about Kaizen of part-time workers three times. On the other hand, the company president also carries out Kaizen too.

Many people may think that the presidents will do great Kaizen, but it is not true. The Kaizen by presidents are also normal.

The president takes a leadership at everyday work and gives instructions. This is a role of the president. However, when it comes to changing every day job by Kaizen, the part-time worker who just entered the company yesterday has equal ability to the president. Because Kaizen is done by ideas and ability to implement which everybody has.

The president is also requested do Kaizen of 5S to keep his or her desk neat and clean.

In this way if every people in a company does Kaizen which may be small at least one per month, it will lead to the innovation for changing total management.

-

2017.08.15

Kaizen by part time worker I talked two times about Kaizen done by the part-time workers who surprised me very much. But these two ladies are not special persons. In fact, everyone has the Kaizen ability without exception.

However, many companies do not ask the part-time workers to do Kaizen activity. Therefore, nobody does it there. Don’t you think that they are missing great possibility?

Find part-time workers whose jobs look difficult and ask how they feel. Then they will explain you how the work is difficult and teach you clearly what they want to do.

If you talk about a solution together with them and carry out Kaizen, quality and efficiency will improve at the moment. If you exchange such a conversation with all the members on the work site every day and continue Kaizen with them, the work will be so easy that efficiency and quality goes up. And the part-time workers may understand that Kaizen leads easy way and they are praised when their work is improved, and Kaizen activity advances steadily.

Kaizen is the work done by all the members together. However small the Kaizen is, management will be improved much if all do it continuously. Let’s do Kaizen together! Please establish Kaizen system that a part-time worker can participate.

-

2017.08.09

Awesome kaizen hidden under the desk Let me continue the stories of Kaizen that a part time worker carried out. There are many impressive Kaizen stories done by part time workers in my mind.

I show you a case of the company Y, a famous measurement instrument maker. Company Y asked me help to stop a big trouble of delivery delay because of the bad production flow in the plant.

There were many assembly processes with many skilled operators and the total processes were divided into five or six small processes. And there were specialized workers for each process.

The production lot size was 50 and 50 units were not handed out until all of them completed by each process, it makes so long time for finishing all the final products. Company Y often faced a big delay on delivery.

When I was discussing with the plant manager on the shop floor, I was aware of a part time worker watching me and I thought she wanted to say something. So, I asked a question to the part time operator Ms. B, “Do you have any good idea?”

Ms. B answered, “I’m sorry, maybe the plant manager gets angry, but when the production is very behind the schedule, I do all jobs by myself piece by piece. In fact, this is much faster but as I do it without permission, I seldom do it.”

“Thank you very much Ms. B. It is excellent! “, I said to Ms. B and asked “Could you do it just now in front of us? I am sorry to ask you suddenly.”

Then Ms. B took out a secret wooden work stand from under the desk and gathered necessary parts and started to assemble products.

What happened? A production time for one piece was only 20 minutes. The plant manager said it took at least a week to finish the products (although the lot size was 50).

The plant manager was surprised to see the production speed and then and there he started the Kaizen to change all the production way from dividing process to assemble by one worker as Ms. B did.

The delivery delay problem was solved in a short time. Ms. B was worried to be scolded, but needless to say, she was praised very much.

This is often the case, that the real solution is staying on shop-floor.

-

2017.08.04

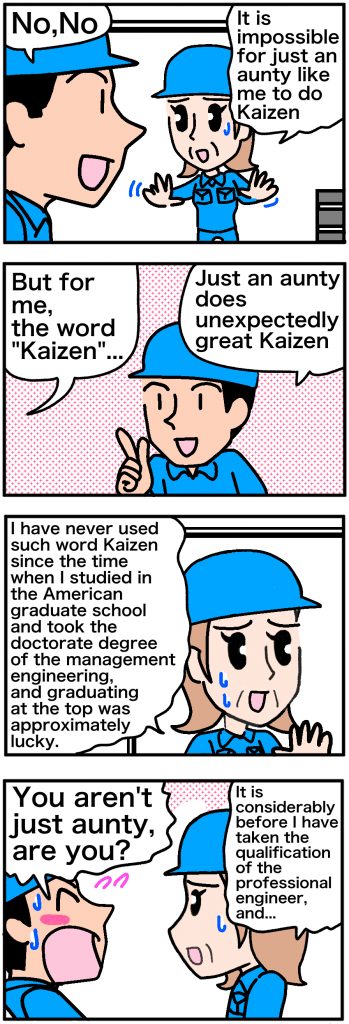

Do with all members. “It is absolutely impossible for just an aunty like me because Kaizen is an expert’s job” Ms. M who is the part time worker of the company K said.

However, a lot of Kaizen was carried out when I saw her work site. For example, gauze was wound around the grip of her cutter and scissors or to use easily, and a ruler was stuck on a work desk to measure the length of the products efficiently.

Therefore, I said to Ms. M, “It is not true, you have already done a lot of Kaizen by yourself. This is a great job!” Ms. M was surprised and said “Oh if these are Kaizen, I am able to do Kaizen much more”. Ms. M surprised and delighted me.

I think that the word Kaizen is sometimes taken exaggeratedly. Kaizen is a small one step to make us comfortable from slightly inconvenient, difficult or troublesome condition to do.

Therefore, changing something even it is really small is an excellent Kaizen. And the management of a company improves if Kaizen is done continuously by all the people in the company.

Even it is a small Kaizen, let’s continue doing it all the time together!